Beyond the Hype: Inside the Science of Textile Recycling with Refiberd

Co-founder Sarika Bajaj on tackling unsolved industry challenges, statistical precision, and material detection realities

The textile recycling revolution sounds promising in theory, but the reality is far messier—and more interesting than most of us realize. In this special edition of Industry Insights, I had a conversation with Sarika Bajaj of Bay Area startup Refiberd. Enjoy this thorough Q&A, accompanied with a MP3 file I edited myself. I’m really excited to share this piece of content with you all - enjoy!

Readers, you are in for a treat! I’m excited to share this in-depth Q&A with Sarika Bajaj, CEO and Co-founder of Refiberd, complete with an audio recording! This project is months in the making, and I’m thrilled it’s finally here.

We first connected during SF Climate Week 2024. As part of the Sustainable Fashion Exhibition production team, I was recruiting speakers for two panel discussions. One of them centered around opportunities for textile’s end-of-life, and Sarika was perfect for that discussion. Refiberd’s use of AI to automatically detect and sort materials based on their fabric compositions was already making waves in the industry, and textile’s end-of-life topics are of perpetual interest of mine.

We have kept in touch ever since, and recently got our schedules aligned to record this interview. We covered a breadth of topics and took a candid look at the reality of the recycling revolution.

Here are a few highlights to look forward to:

Challenges of identifying and communicating what materials are in our clothes

Whether Refiberd’s AI technology can detect PFAS (forever chemicals) in fabrics

Sarika’s experience as a female co-founder of a startup pioneering textile recycling solution

Fiber detection technology applications beyond apparel industry

Whether my mixed-material Gathered Cloths project can be recycled effectively in this lifetime

We dove straight into these topics and more! We had a great time discussing how up to 40% of clothing labels may be inaccurate, and how her team has found everything from Mercedes keys to questionable undergarments in textile samples.

All in all, this interview offers a rare glimpse into the B2B world of textile innovation — complete with both the sobering realities and unexpected possibilities that come with trying to solve one of fashion's biggest problems.

Please enjoy the recorded interview below! It’s definitely my favorite Q&A so far, and I’m really grateful to Sarika for sharing her insightful look at the current textile recycling reality!

Transcript and Notes

Below is the transcript for you to listen and read along. I also put category headings, timestamps, and additional missing words for reference and easier reading. Or, if you prefer reading only, this transcript will give you a full context of what Sarika and I talked about!

Getting to Know Sarika & Refiberd

(0:01) Mira Musank: Sarika, it's so good to have you here. I'm so glad that we are able to do this Q&A, and I'm super excited to have the Fafafoom Studio Newsletter readers to know more about you.

So can you introduce yourself and tell us what Refiberd does for our readers who might be new to textile recycling technology?

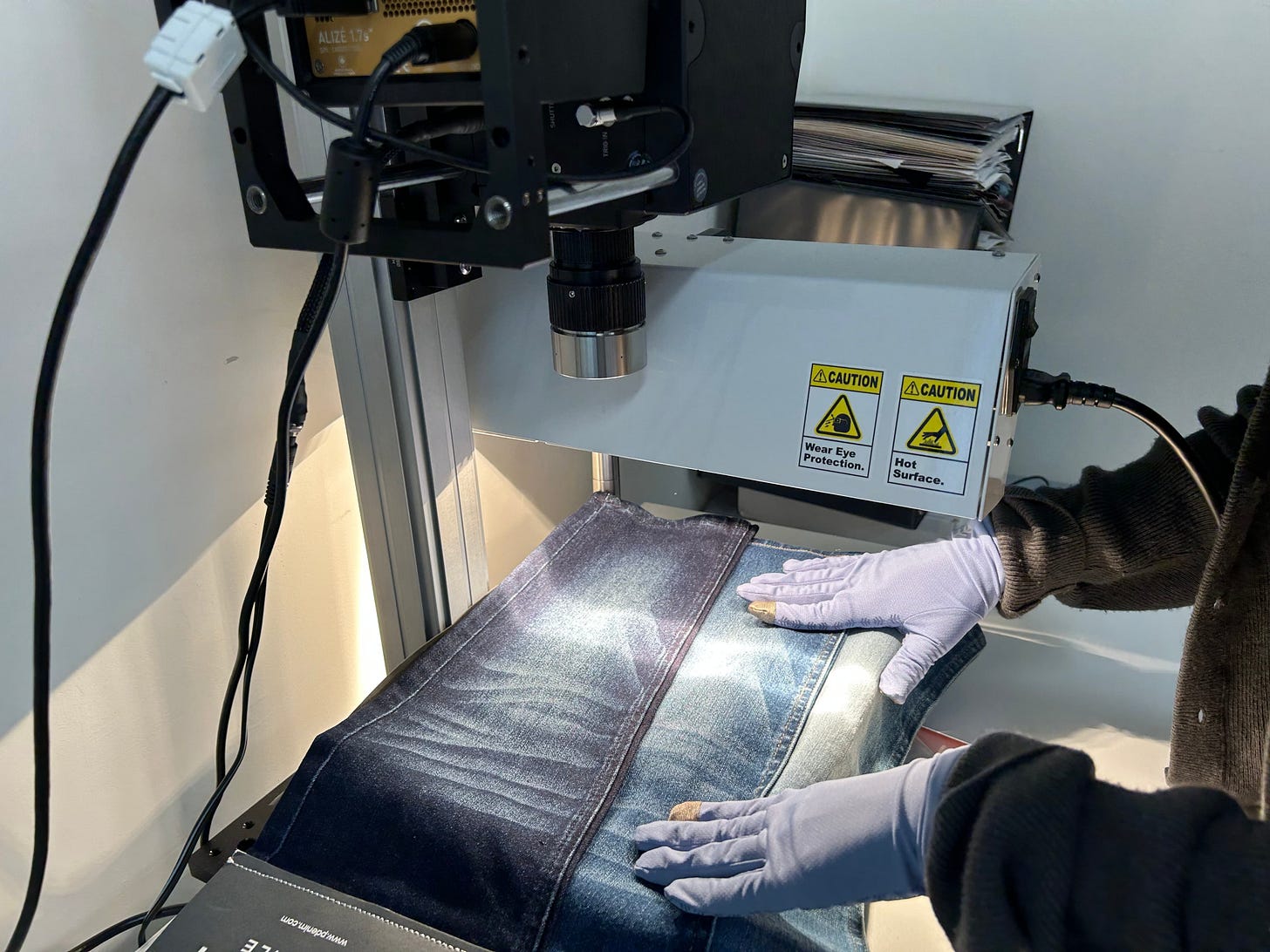

Sarika Bajaj: Absolutely. Thank you for having me, Mira, I’m excited to be here. I'm Sarika, co-founder of Refiberd. Essentially, what we do is we use a sensor called a hyperspectral camera. It acts kind of like a video camera, except it uses near-infrared light.

So instead of visible light that we're used to, near-infrared is in a slightly different part of the spectrum. It basically captures all of this data on how near-infrared light is absorbed and reflected, just the way a normal camera does.

And the part that Refiberd has developed is a way to properly process all of that data to come up with a very accurate material composition of textiles.

So without trying to get too deep into everything, usually what we end up getting between absorption and reflection is a graph that we call the spectra, which kind of shows us those peaks and dips.And that changes based on the material you're looking at.

Now, the really hard part of this problem is when you have material blends like we see in textiles, and all contaminants and everything like that, which can very subtly change the textiles.

So if you see a slight variation in the peak and the dip, is it because there's 2% elastane?

Is it because of wax coating or waterproof coating on the garment? What is causing that issue?

And are there actually other trends in that graph as well that tell us how much more information that we as humans aren't necessarily good at perceiving?

Keep reading with a 7-day free trial

Subscribe to Fafafoom Studio Newsletter to keep reading this post and get 7 days of free access to the full post archives.